There’s a moment I think about often. I was standing in the backroom of a mid-sized sporting goods retailer, surrounded by boxes of winter jackets that had arrived three weeks too late. The season was basically over. Markdown city. Meanwhile, their running shoe inventory was so depleted that sales associates had spent the past month apologizing to customers and hoping they’d check back later.

The store manager looked exhausted. “We ordered based on last year’s numbers,” she told me. “It’s the same thing we’ve always done.”

That conversation happened about eight years ago. Today, this retailer uses machine learning algorithms that factor in weather patterns, local events, social media trends, and dozens of other variables to predict demand. Their overstock situations have dropped by roughly 40%, and stockouts are down even more. Same store, same manager, completely different results.

I’ve spent the better part of fifteen years working in retail operations and supply chain consulting, and I can say without hesitation that artificial intelligence has fundamentally changed how smart retailers think about inventory. Not as a silver bullet—it’s definitely not that—but as a genuine competitive advantage when implemented thoughtfully.

The Inventory Problem That Never Really Goes Away

The same issue plaguing every retailer, regardless of whether he has a single boutique or thousands, is this, you need to ensure that you have stock enough to meet demand without having so much that you are left with leftovers.

Under-stocking means lost sales. Clients walk away with no products or head to a rival. With over-stocking, you incur markdowns, storage expenses and you also have the risk of products expiring or becoming outdated before they can sell.

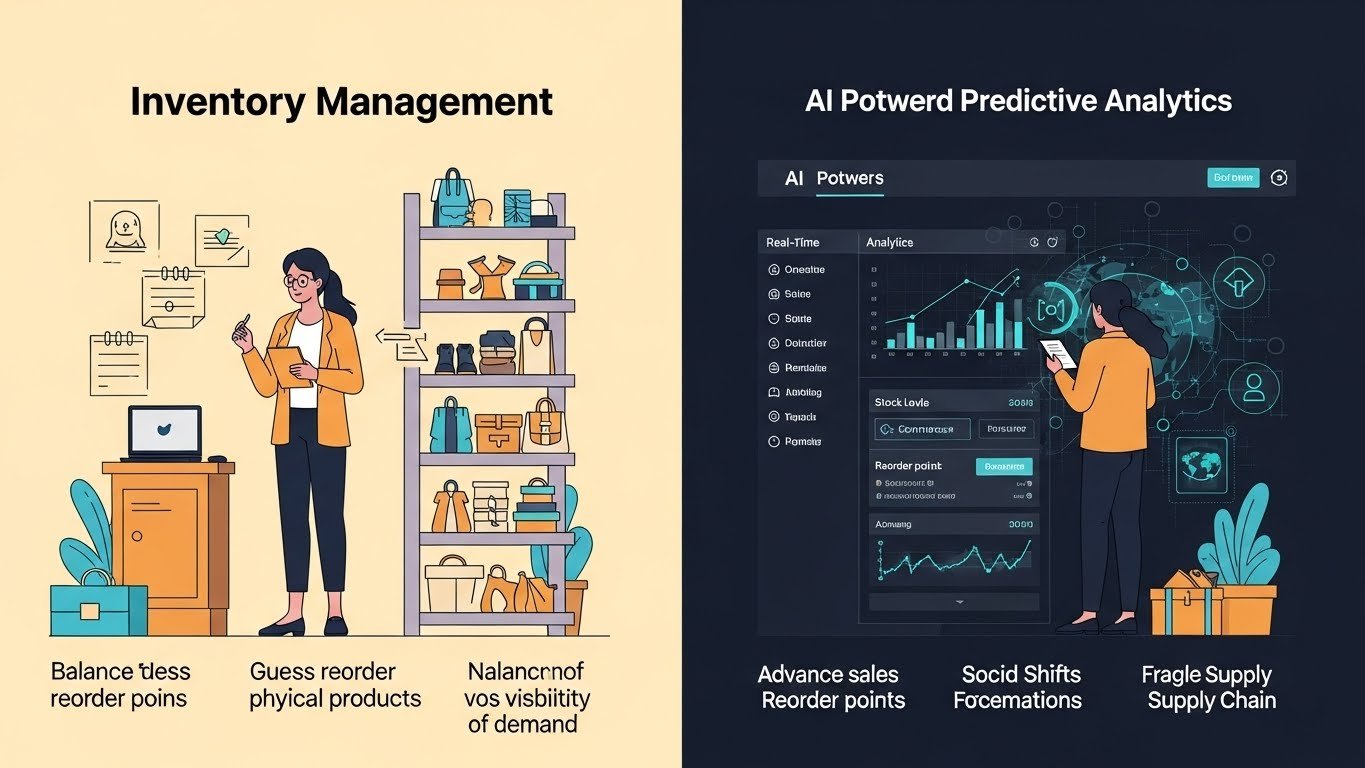

The conventional inventory control was primarily based on previous sales information, intuition, and informed speculation. Buyers would check the sales of last year, make the required adjustments, and make orders taking into consideration the safety factor.. Reorder points were set somewhat arbitrarily. Safety stock levels were often based on gut feel rather than statistical analysis.

It was a complementary strategy to the ease of retail. Forecasting on experience was adequate due to the presence of predictable seasons, reliable supply chains, and customers purchasing the same products annually.

Retail has become very complicated now. The taste of consumers evolves within few days. Social media has the capability of boosting demand of a single product within a night. The amount of crisis in global supply chains is weak–as the pandemic demonstrated. The e-commerce introduces additional challenges: store-to-store, store-to-store, online purchase and pick-up, and day-delivery.

The previous methods of inventory management are clearly not sustainable.

Where AI Actually Makes a Difference

Let me break down the specific applications where I’ve seen artificial intelligence deliver real value in inventory management. Not theoretical value—actual improvements in real retail operations.

Demand Forecasting That Actually Works

Traditional forecasting typically looked at sales from the same period last year, maybe adjusted for trend. If you sold 100 units of something last March, you might plan for 105 this March if you’re seeing modest growth.

AI-powered demand forecasting takes an entirely different approach. Modern machine learning models can incorporate hundreds of variables simultaneously:

- Historical sales data (of course, but analyzed at much finer granularity)

- Weather patterns and forecasts

- Local events and holidays

- Economic indicators

- Competitor pricing and promotions

- Social media sentiment and trending topics

- Search engine query volumes

- Day of week and time of month patterns

- Marketing calendar and promotional plans

A grocery client I worked with implemented this kind of multi-factor forecasting for their produce department—one of the hardest categories to manage due to short shelf life. They reduced waste by 23% in the first year while actually improving product availability. The system learned, for example, that avocado sales spike during weeks with televised sporting events (apparently guacamole consumption is highly correlated with watching sports at home). No human analyst had ever made that connection.

The real power comes from the models continuously learning. They don’t just apply static rules; they adjust based on what’s actually happening. When a prediction is wrong, the system analyzes why and refines its approach.

Automatic Reorder Point Optimization

Setting reorder points—the inventory level that triggers a new purchase order—has traditionally been more art than science. Set them too high, and you’re carrying excess inventory. Set them too low, and you risk stockouts.

AI systems calculate optimal reorder points dynamically, adjusting based on:

- Current demand patterns (not just historical averages)

- Supplier lead time variability

- Expected demand volatility

- Cost of carrying inventory vs. cost of stockouts

- Upcoming events that might affect demand

I watched a home improvement retailer implement this kind of dynamic reordering and reduce their average inventory investment by 18% while simultaneously improving in-stock rates. The system recognized, for instance, that certain suppliers had become more reliable over time and adjusted safety stock down accordingly. It also knew that demand for outdoor furniture spiked earlier in warm weather regions, so it staged inventory differently by geography.

The key insight is that optimal inventory levels aren’t static. They should change constantly based on conditions. Humans simply cannot recalculate these parameters continuously across thousands of SKUs, but machine learning systems do it routinely.

Multi-Location Inventory Balancing

For retailers with multiple stores or warehouses, another challenge emerges: you might have adequate total inventory, but it’s in the wrong places. Store A has surplus while Store B is sold out.

AI-powered inventory balancing systems identify these imbalances and recommend transfers before stockouts occur. Some advanced implementations even predict which locations will need product before current stock runs low, enabling proactive redistribution.

A fashion retailer I consulted with was experiencing this constantly. Certain styles would sell out in urban locations while sitting unsold in suburban stores, or vice versa. Manual transfers happened, but usually after the damage was done—after customers had already been turned away.

Their AI system now monitors sell-through rates at every location and flags imbalances when there’s still time to act. It even accounts for transfer costs, recommending moves only when the sales opportunity justifies the expense. Their network-wide in-stock rate improved by roughly 12 percentage points.

Loss Prevention and Shrinkage.

Theft, damage or administrative errors that cause inventory shrinkage cost retailers billions a year. Conventional approaches measure shrinkage when it is already too late, when the physical counts are performed, and consequently the question arises how the loss took place.

AI offers loss prevention that is predictive. Systems scan transaction trends and spot abnormalities and issue alerts in real-time.. They can detect:

- Unusual void or discount patterns at specific registers

- Return fraud indicators

- Receiving discrepancies that suggest vendor fraud or error

- Patterns that indicate organized retail crime

One grocery chain I know implemented machine learning for shrinkage detection and identified a receiving fraud scheme they’d never noticed—a driver was systematically short-delivering orders while paperwork showed full deliveries. The AI spotted the pattern across multiple locations and vendors. The recovery was substantial.

Beyond theft, AI helps with damage reduction by identifying handling patterns, storage conditions, or supplier issues that lead to product damage. It’s less dramatic than catching fraudsters but often more financially significant.

Promotional Planning and Impact Prediction

Inventory management can be interfered with by promotions. When you make a sale but you do not have sufficient stock then customers become frustrated. When you place excessive orders when promoting something that does not do so well, you are left with excess stock.

Based on the previous promotional data, AI models can be trained in such a way that they can predict the effect of various promotions on demand with a high degree of accuracy. They recognize the products that are very responsive to sales and those that are somewhat inelastic. They also record the concept of cannibalization that the promotion of one good takes away the sales of the other close products.

One of the consumer-electronics retailers that I was assisting has been planning inventory based on Black Friday and holiday promotions using AI. Previous years were destructive: there were several door-buster products that would be sold in a matter of hours, and those that did not sell at all.. The AI-driven approach improved their promotional inventory accuracy dramatically. More products stayed in stock through the promotional period without massive overstock afterward.

Supplier Performance and Risk Management

The inventory does not only encompass the items that are held in the warehouse but those in the transit and those that are on order. Through AI systems, retailers can manage the relationship with suppliers and reduce the risks in supply-chains in a more productive manner.

Through evaluation of the supplier performance data, on-time delivery rates, quality matters, and lead-time deviation AI can:

- Find other suppliers in case of risk by the primary sources.

- Automatic adjustment of safety stock according to the reliability of suppliers.

- Anticipate possible supply interruptions and they do not affect inventory.

- Optimize the amount and time of order with each supplier.

In the 202022 supply-chain anarchy, retailers having advanced AI surveillance fared far better than conventional operations. They were able to sense disruptions in advance and had a greater time to respond.

Returns Management and Reverse Logistics

Returns are a growing challenge, especially for e-commerce. AI helps manage this reverse flow more intelligently:

- Predicting return rates for products based on category, price, reviews, and customer behavior

- Determining optimal disposition for returned items (resell, refurbish, liquidate, donate)

- Identifying fraud patterns in returns

- Adjusting forward inventory based on expected return volumes

A fashion e-commerce client saw roughly 30% return rates on certain categories—essentially normal for online apparel. Their AI system learned to order additional inventory anticipating returns, and also got better at identifying which products were likely to have high return rates before they were even purchased. They could then add more detailed sizing information or customer photos to reduce returns before they happened.

The Implementation Reality

I want to be honest about what implementing AI for inventory management actually involves, because the vendor marketing materials make everything sound too easy.

Data Is the Foundation—And Often the Biggest Obstacle

AI systems need clean, comprehensive, historical data to learn from. Many retailers discover their data is messier than they thought. Point-of-sale systems don’t always integrate cleanly with inventory management systems. Historical data might be incomplete or inconsistent. Product hierarchies change over time.

Before any AI implementation, expect a significant data cleanup and integration effort. At one retailer I worked with, this phase took eight months—longer than the actual AI deployment. But without solid data foundations, the models simply can’t work effectively.

Start Narrow, Then Expand

The most successful implementations I’ve seen started with a specific, bounded problem rather than trying to transform everything at once. Maybe it’s demand forecasting for a single product category. Maybe it’s reorder optimization for a subset of suppliers. Prove value in one area, learn from the experience, then expand.

A grocery chain I advised started with their dairy department—high volume, relatively predictable demand patterns, significant waste costs if managed poorly. They got that working well over about six months, then gradually expanded to produce, then to center store. The phased approach let them build organizational competence while demonstrating ROI to justify continued investment.

The Integration Challenge Is Real

Most retailers aren’t building inventory systems from scratch. They have existing ERP systems, warehouse management systems, point-of-sale systems, and supplier portals. AI solutions need to integrate with all of these, which is rarely seamless.

Expect integration work. Budget for it. Some of the “failed” AI implementations I’ve seen weren’t really AI failures—they were integration failures. The models worked fine; they just couldn’t get the right data in or push recommendations out to the systems that needed them.

Change Management Matters More Than Technology

Here’s what vendors rarely mention: the hardest part isn’t usually the technology. It’s getting people to trust and use the system.

Inventory managers and buyers have often been doing their jobs for decades. They have intuition, relationships, and experience that they trust more than a black-box algorithm. When the AI says to order 500 units and their gut says 300, guess what many of them do?

Successful implementations invest heavily in change management. This means:

- Showing users how the models work (at least conceptually)

- Starting with AI as a recommendation engine rather than automated decision-maker

- Celebrating wins and analyzing failures transparently

- Giving users override capability while tracking outcomes

- Building trust gradually through demonstrated accuracy

One retailer I know runs their AI recommendations alongside human decisions for the first six months in each new category. They track which performed better, share the results with the team, and only move to automation once the humans themselves are convinced. It takes longer, but adoption is much smoother.

What AI Can’t Do (Yet)

I believe this technology, however, I think we need to be honest about its limitations.

It Suffers with Real Innovation.

AI is informed by trends in past information. Where something veritable never happened before, like a product that is not similar to any product you have ever sold, a completely new behavior of customers, or a black swan event, the models have nothing to imitate.

During the early pandemic, AI inventory systems were largely useless for predicting demand. They had never seen a pattern where toilet paper sales went up 700% while restaurant supplies went to zero. The models were predicting normal March patterns when nothing was normal.

Human judgment remains essential for situations without historical precedent.

It Can’t Replace Relationship Intelligence

Much of inventory management involves relationships—with suppliers, with internal stakeholders, with customers. AI can tell you that a supplier’s reliability metrics are declining. It can’t tell you that they’re going through a leadership transition that you know about from your rep, and things will improve in a quarter.

Experienced buyers and planners have context that doesn’t exist in data. The best AI implementations augment this human knowledge rather than ignoring it.

It’s Only as Good as the Inputs

In case there is an error in your point-of-sale data, AI will be trained on wrong patterns. Reorder recommendations are not accurate when there are inaccurate inventory counts. Unless you mark down reasons or promote flags, the system cannot be able to know why the sales went down.

The law of garbage in, garbage out stands.

It Has the Potential to bring spurious faith.

Advanced AI systems may provide their users with overconfidence. They come up with accurate looking predictions, say 427 units rather than 400 450 units, which conceal the uncertainty.

There are smart retailers who follow prediction accuracy at any given time and formulated realistic expectations regarding the reliability of the system that can and cannot predict.

Considerations of Ethics Worth Thinking.

This part may not be part of an article dealing with inventory-management, but it counts.

Workforce Implications

AI does not take away inventory-management jobs, it just changes them. The positions of manual planning and calculations are replaced by the exception handling and strategic management. Certain jobs are very well possible to be rendered obsolete.

The retailers implementing such systems have to respond to workforce changes. Do you know that displaced planners can be retrained in other positions? Do they have new vacancies that they can fill? These are not only ethical questions, but practical ones. Being too pushy with AI implementation without planning the workforce is an invitation to a counter-influence that will disrupt the implementation.

Supplier Relationship Fairness.

Biases may be incorporated in AI systems used to assess the performance of suppliers and recommend sourcing choices. A tiny supplier who had issues with delivery in the first year, but has since made advances may always lose at the hands of an algorithm that prioritizes initial information. Automated decisions also may have no context that the human relationship managers would utilize.

Assess AI-supplier decisions on a regular basis. Ensure that there are no systematic handicaps to particular types of vendors, which do not correspond to the actual reality of current performance.

Sustainability Implications

On the positive note, improved inventory control usually minimizes waste, fewer products are produced and land in the garbage field, less food waste, and over production. Forecasting based on AI is indeed beneficial to sustainability.

The risk is there is also the likelihood that efficiency gains only work to accelerate overall consumption. The sustainability computation is not that simple.

Where This Is All Heading

I wanted to give some reflections on trajectory based on what I am observing in the field.

Inventory autonomous management.

We are heading to systems which do not only recommend, but implement. Automatic reordering is already becoming the norm, and we will have even more fully autonomous inventory ecosystems with human intervention being limited to a strategic and exception based form.

I do not believe that we are quite there yet, trust has to be established, edge cases have to be resolved. But the direction is clear.

Physical Operations Integration.

Robotics and automation will be more attached to AI-based inventory systems. Robots moving autonomously in the warehouse controlled by AI inventory systems, intelligent shelves that scan inventory and signal replenishment and drone-based count of inventory.

These links are already occurring in the state-of-the-art distribution centers and they will be more prevalent.

End to End Supply Chain Intelligence.

The use of inventory will be further integrated into the overall supply chain coordination. AI systems will look at the suppliers of raw materials all the way to manufacturing, to the product distribution, to the shelf of the store- not to your shelf. This visibility allows a lot more advanced optimization.

Custom Inventory on an Individual Scale.

With retailers becoming more knowledgeable about the tastes and preferences of individual customers, there will be more localized and personalized inventory assortments. However, not merely being equipped with the right inventory to suit a region, but the right inventory to suit your own customer base all the way down to the store level.

Profitable Recommendations to Retailers to That End.

Inventory management is a key area an AI can be used in, and in the event that you are running an operation or advising a retail and you are thinking about AI, this is what I would recommend after observing numerous implementations, both success and failure.

check the data preparedness first.

Be honest when analyzing your data condition and speaking to vendors or comparing solutions. Are you able to know the exact inventory levels of all the locations at this moment? Do you have the ability to a pull clean historical sales information at SKU-location-day level? Does it have product attribute information that would allow algorithms to know similarity of items? In case the answers are no or sort of, then begin there. There will be a failure in the implementation of AI on unstable data platforms.

Establish Such Success Measures Beforehand.

What would success look like? What percentage of stockouts are reduced? By what percentage will inventory carrying costs be reduced? Decreased markdown losses? In the absence of pre-established metrics, you will not be able to assess the success of investment. I have witnessed too many implementations which were declared successful or unsuccessful on the basis of vibes and not evidence.

Begin with Low-Complexity, High-Impact Categories.

All types of inventory do not lend themselves to AI. Start where you have:

-High volume and historical data is good.

- There is a high price of failure in it.

- Relatively functional patterns (not fashion-oriented or a trend-following)

- Reduced extraneous factors to model.

Basic items such as grocery, simple clothing, health and beauty, are usually good places to start. Take a back seat to the cutting-edge fashion or highly promotional category until after you have established competence.

Invest in Your People Like you invest in your Technology.

The technology does not apply itself. You have to have individuals who are familiar with the business and technical systems. Make investments in training, recruit based on analytical skill, and develop a role that acts as a transition between data science and operations. The retailers who will benefit most by AI inventory management are those ones with effective teams that translate technical capability in the business application.

Be Realistic with Expectations.

AI will enhance your inventory management. It won’t perfect it. You still will have stockouts and overstocking scenarios. Ambition is not perfection but excellence. Have expectations, have them with the leadership (to receive follow-up help in times when things are not ideal) and with your employees (so that they do not impose that AI means that they no longer need to think).

The Bottom Line

Since we have been in retail operations these many years, there have been a lot of technologies here and there. This is not true of AI-based management of inventory. It’s not a fad. Those retailers that effectively learn it will be able to gain actual, lasting competitive advantage, of higher customer experience by having better availability, higher margins by having lower waste and carrying costs, and greater responsiveness to fluctuating circumstances.

But it’s also not magic. It demands an investment on data, technology and people. It involves change in the organization. It entails having realistic expectations regarding things that can and cannot be done.

That sporting goods store, which I referred to at the first, the one of the late jackets and of the missing running shoes, is among my favorite success stories because they did the job. They tidied their information, thoughtfully imported technology, developed teams and began small and then grew as they gained competence.

They do not have an ideal inventory management at the moment. They still have challenges. But their buyers take time to calculate strategy and exceptions instead of manually calculating. They find what their customers want more frequently and their margins have been improved.ooks like in practice: not a revolution overnight, but steady, substantial improvement that compounds over time. And honestly, that’s more valuable than any magic wand could ever be.